Acknowledge of Ultrafiltration Membrane

2022-04-14

Ultrafiltration is a membrane permeation separation technology that purifies, separates or concentrates the solution. It has developed rapidly for more than 20 years and has become one of the most widely used technologies in the field of membrane separation. It has a wide range of applications from household water purifiers to modern industrial production. Ultrafiltration Membrane is one of the most promising membrane separation technologies.

I. Types of Ultrafiltration Membrane Module

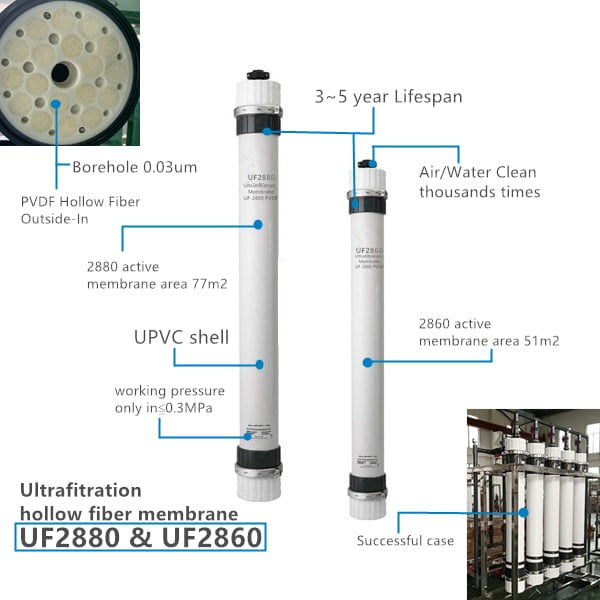

At present, the Ultrafiltration Membrane Module commonly used in industry mainly include the following five types: plate type, tube type, roll type, hollow fiber type and capillary type. Each basic type of membrane has different applicability, and hollow fiber type is the most widely used in industry, especially in purification and separation applications.

II. Characteristics of Ultrafiltration Membrane

In the field of membrane separation technology, the separation accuracy of ultrafiltration is between nanofiltration and microfiltration. The domain of Hollow Fiber Ultrafiltration is about 500 ~ 500,000 cutoff molecular weight. Like a sieve, ultrafiltration membrane allows solvent and solute smaller than the pore diameter of membrane to pass through under a certain pressure (0.1 ~ 0.6 MPa), but prevents solute larger than the pore diameter from passing through, so as to purify, separate and concentrate the solution. Ultrafiltration process has the following characteristics:

(1) The ultrafiltration process has no phase change and can be separated at room temperature and low pressure, so the energy consumption is low, which is about 1/2 ~ 1/5 of that of evaporation and freezing;

(2) The equipment is small in size and simple in structure, so the investment cost is low and it is easy to implement;

(3) The ultrafiltration separation process is just a simple pressurized liquid conveying process, with simple process flow and easy operation and management;

(4) The solution does not change qualitatively in the process of separation and concentration, so it is suitable for the treatment of taste-preserving and heat-sensitive solutions;

(5) It is suitable for the recovery of trace precious macromolecular substances separated from dilute solution and the recovery of low concentration macromolecular substances;

(6) substances with different molecular weights can be separated by stages;

(7) Ultrafiltration membrane is a uniform continuous body made of high-molecular polymer, without any impurities falling off during use, so as to ensure the purity of the treated solution.

III. Structure of Ultrafiltration Membrane

The structure of Ultrafiltration Membrane Manufacturer can be divided into symmetric and asymmetric. The former is isotropic, has no cortex, and the pores in all directions are the same, which belongs to deep filtration; The latter has a dense surface layer and a finger-shaped bottom layer, the thickness of the surface layer is 0.1 micron or less, and it has ordered micropores, and the thickness of the bottom layer is 200 ~ 250 microns, which belongs to surface filtration. Ultrafiltration membranes used in industry are generally asymmetric membranes. The membrane materials of ultrafiltration membrane mainly include cellulose and its derivatives, polycarbonate, polyvinyl chloride, polyvinylidene fluoride, polysulfone, polyacrylonitrile, polyamide, polysulfone amide, sulfonated polysulfone, cross-linked polyvinyl alcohol, modified acrylic polymer and so on.

IV. Ultrafiltration membrane filtration

Ultrafiltration membranes are mostly made of acetate fiber or polymer materials with similar properties. It is most suitable for the separation and concentration of solutes in solution, and it is also commonly used for the separation of colloidal suspensions which are difficult to be completed by other separation technologies, and its application field is constantly expanding.

V. Process characteristics

Membrane filtration driven by pressure difference can be divided into ultrafiltration membrane filtration, microporous membrane filtration and reverse osmosis membrane filtration. They are distinguished according to the minimum particle size or molecular weight that can be retained by the membrane layer. When the rated pore size range of membrane is used as the criterion, the rated pore size range of microporous membrane (MF) is 0.02 ~ 10μ m; Ultrafiltration membrane (UF) is 0.001 ~ 0.02 μ m; Reverse osmosis membrane (RO) is 0.0001~0.001μm m. Therefore, ultrafiltration membrane is most suitable for the separation and concentration of solute in solution, or the separation of colloidal suspension which is difficult to be completed by other separation technologies. The technology of obtaining micropores with expected size and narrow distribution is extremely important for ultrafiltration membrane technology. There are many factors controlling pore size. For example, Ultrafiltration Membranes Filter with different pore sizes and pore size distributions can be obtained according to the type and concentration of solution, evaporation and coagulation conditions during membrane preparation.